Where Innovation Takes Shape

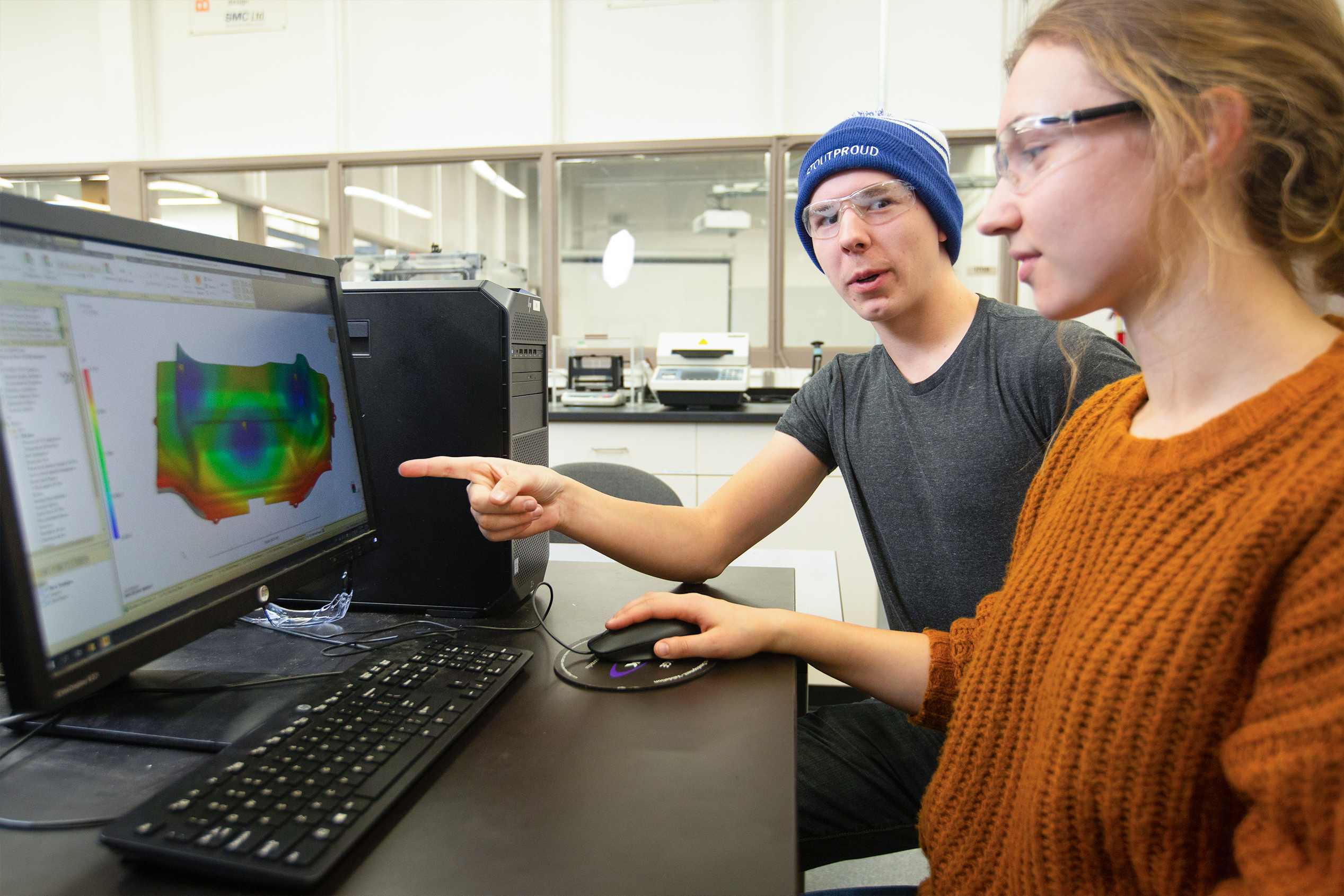

Our Plastics Engineering Lab comprises a classroom, a plastics processing area and a plastic materials characterization lab. Featuring a range of equipment and software to design, simulate and manufacture plastic products, the lab heavily focuses on processing techniques, including injection molding, extrusion, thermoforming, blow molding and rotational molding.

UW-Stout’s B.S. Plastics Engineering program is internationally recognized and supported by leading companies who value our graduates’ experience with innovative processes and industry-leading equipment. With the help of our industry partners, UW-Stout is home to one of the nation’s premier plastics engineering labs.

Dive Deeper Into the Plastics Engineering Lab's Equipment

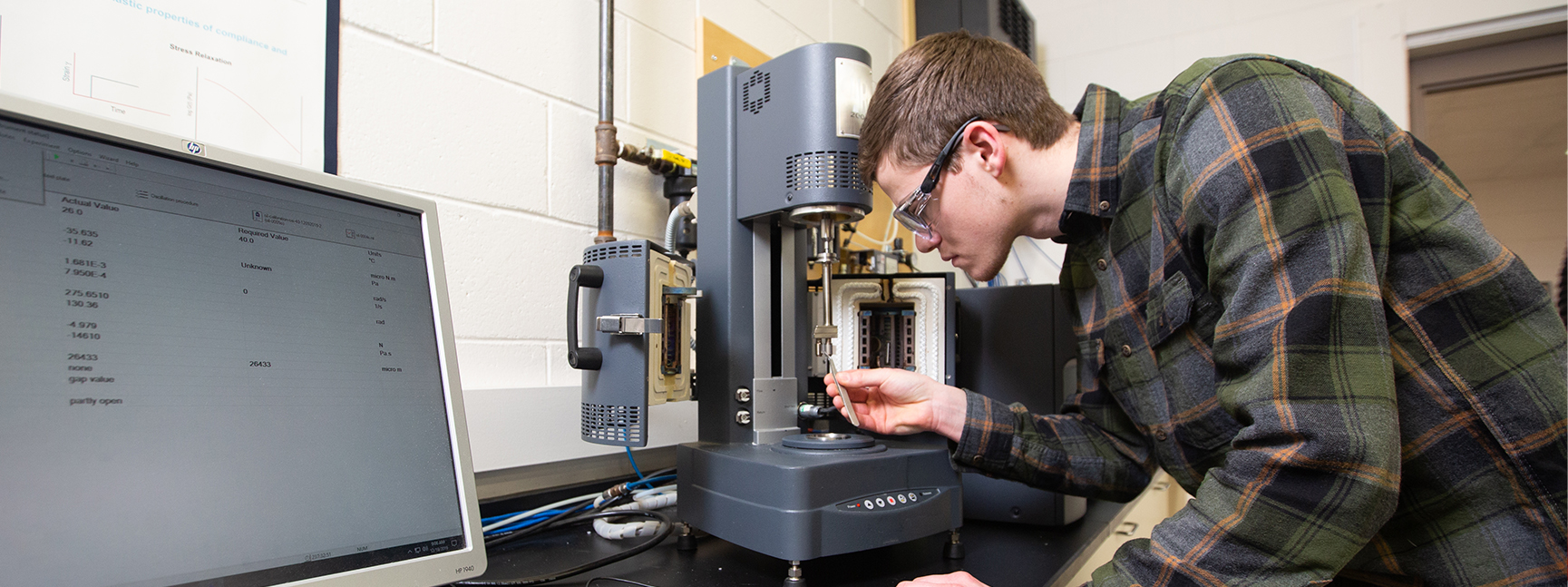

Plastics Analysis

From the molecular intricacies to batch consistency, this is where you engage with cutting-edge tools for comprehensive plastics characterization.

Delve Deep into Plastics Science

Welcome to the Material Characterization section. Discover the core science that drives plastics engineering, and gain hands-on experience using our state-of-the-art tools.

Equipment Highlights

Thermal Analysis

Unlock the secrets of how plastics react to temperature changes. Ideal for students interested in material behavior and essential for industries needing to meet specific thermal requirements.

DNA, DSC, TTA

Dive into Differential Scanning Calorimetry (DSC), Dynamic Mechanical Analysis (DMA), and Thermo-Mechanical Analysis (TTA) to study the physical properties of plastics. Understand the material transitions that are critical for both academic research and industrial applications.

Capillary Rheometer

Measure the flow behavior of molten plastics with high precision. This tool is a staple in both academic labs for mastering rheology principles and in industry for quality control.

Stress, Strain, and Success

Step into the Mechanical Testing section, where materials meet their match. Whether you're looking to grasp the fundamentals or seeking robust data, our advanced testing tools have you covered.

Equipment Highlights

Mechanical Testing

Get up-close with standard tensile, compression, and flexural tests. Perfect for students learning the basics of material science and indispensable for industries requiring rigorous material evaluations.

Bending Compression Testing

Explore the resilience of materials under bending forces. Essential for both academic studies of mechanical behavior and for industrial applications where materials need to maintain integrity under stress.

Where Precision Meets Excellence

Unlock the potential of the next generation of plastics engineering tools in our Advanced Analysis & Quality Control section.

Equipment Highlights

3D Printers

Bring your designs to life with our high-precision 3D printers. A must-have for students keen on rapid prototyping and a game-changer for industries focused on quick, cost-effective product development.

FTIR Spectroscopy

Probe the molecular architecture of plastics and polymers. Vital for students seeking a deeper understanding of material science and indispensable for industries looking for detailed compositional analysis.

Melt Flow Indexer

Gauge the viscosity of molten plastics with pinpoint accuracy. Crucial for academic research into material properties and essential for industrial quality control.

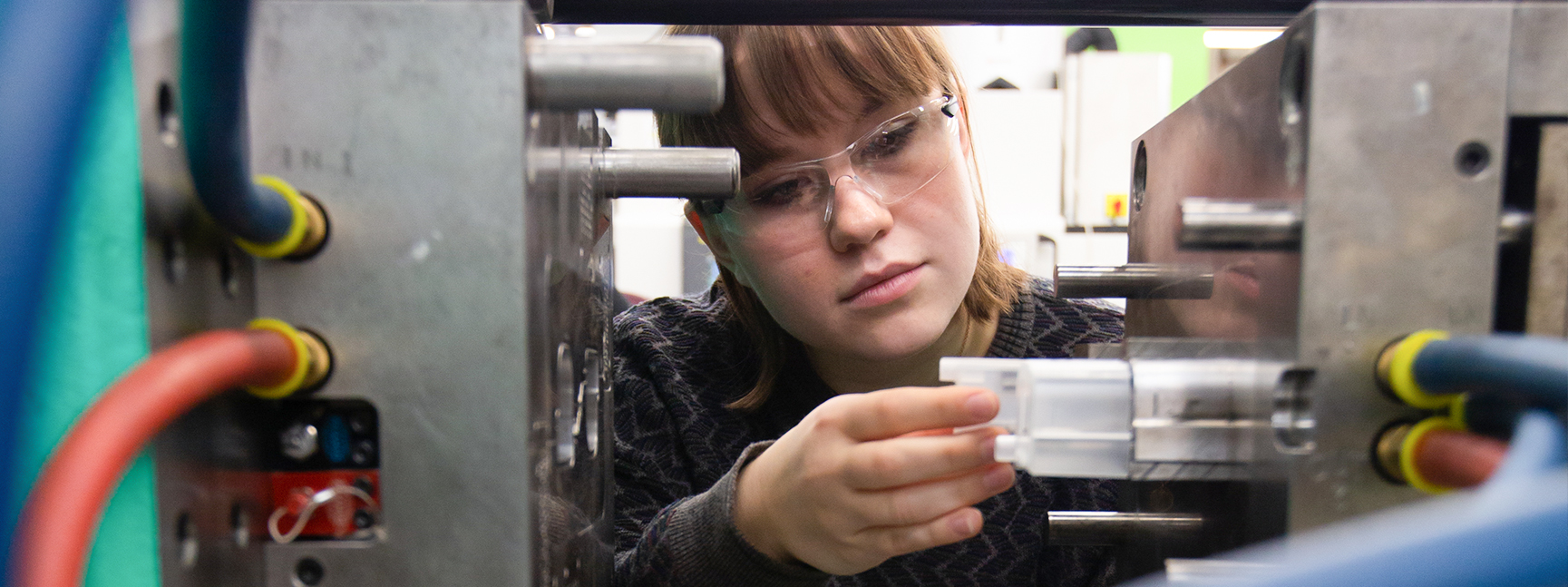

Plastics Processing

Step into the heart of plastics innovation. Our expansive lab area is where raw materials transform into functional products. With top-of-the-line injection molding machines and versatile extruders, your hands-on journey in plastics engineering begins here.

Your Gateway to Versatility

Whether it's hot or cold, our injection molding stations offer unparalleled versatility. Our suite of six top-tier machines from brands like Milacron, Engel, TOYO, and Arburg sets the stage for diverse project needs.

Key Equipment

Injection Molding Machines: Six units for tackling varied manufacturing requirements.

Hot and Cold Molding Capabilities: Experience both high-temperature and low-temperature molding processes.

Trusted Brands: Machines from industry leaders Milacron, Engel (e-motion 85), TOYO, and Arburg ensure quality and reliability.

The Extruders' Arena

Experience the transformative power of extrusion in our Plastics Processing section. If you're a student eager to master advanced processing techniques our suite of extruders is the playground you need.

Equipment Highlights

Multi-layer Co-Extrusion

Take your skillset to the next level by manipulating multiple materials in a single process. Ideal for students exploring complex material behaviors and crucial for industries requiring multi-material components.

Case Film Extrusion

Discover the technology behind high-quality packaging materials. Perfect for students interested in specialized applications and vital for industries in packaging and product protection.

Filament Extrusion

Create high-quality filaments used in 3D printing and other applications. An essential skill for students focusing on rapid prototyping and invaluable for industries needing consistent, reliable filaments.

Specialized Techniques

Welcome to the Specialized Techniques Section, your secluded haven for advanced plastics engineering. Beyond our main lab, this space offers specialized machinery for nuanced techniques in molding, welding, and material testing.

Shape Your Future

Non-woven Extrusion Line

Master the art of creating non-woven fabrics. This is a key area for students focusing on textiles and is invaluable for industries like healthcare and automotive that rely on specialized materials.

Dive into the world of specialized molding techniques in our Advanced Molding Systems area. Whether you're an aspiring student or an industry leader, our diverse array of equipment sets the stage for innovation and excellence.

Equipment Highlights

Non-woven Extrusion Line

Master the art of creating non-woven fabrics. This is a key area for students focusing on textiles and is invaluable for industries like healthcare and automotive that rely on specialized materials.

Thermal Formers

Two small and one large thermal former allow you to create products from yogurt cups to automotive components. Perfect for students with a broad interest in material applications and essential for various industrial needs.

Compression Molder

Get hands-on experience in transforming plastic granules into finished components. Great for students studying material transformation and a must-have capability for any industry focused on mass production.

Blow Molder

Delve into the creation of hollow plastic parts. Important for students looking to work in packaging or container manufacturing and critical for industries requiring high-quality hollow components.

Rotational Molder

Learn the rotational molding process to create large, hollow objects. Ideal for students interested in large-scale manufacturing techniques and indispensable for industries like automotive and storage solutions.

Fusing Science and Innovation

Unearth the intricate world of ultrasonic welding. Tailored for students keen on mastering advanced joining techniques and high-precision manufacturing.

Equipment Highlight

Ultrasonic Welder by Branson

Step into the future of plastics joining with our Branson Ultrasonic Welder. This is an invaluable tool for students wanting to delve deep into assembly processes and is a cornerstone for industries that require ultra-precise, high-speed welding.

Your Forecast for Success

Explore the resilience of materials with our Accelerated Weathering Tester. The equipment allows students to understand the longevity of materials under environmental stressors.

Equipment Highlight

QUV Accelerated Weathering Tester

Accelerate your understanding of material degradation with our QUV Accelerated Weathering Tester. This equipment mimics the effects of environmental stressors like sunlight, rain, and dew using advanced UV lamps and moisture cycles. Whether you're a student looking to understand material lifespans or an industry professional seeking reliable, long-term performance data, the QUV Tester is an indispensable asset.

Industry Partners & Donors

When you step into our Plastics Engineering Lab, you're stepping into a hub of industry collaboration. Our lab is outfitted with state-of-the-art equipment and resources, thanks to partnerships with global leaders in the field. For students, this means access to the very same tools you’ll encounter in your professional career, right here on campus.

Meet Our Esteemed Partners

- Arburg (Germany)

- Engel (Austria)

- Milacron (Ohio)

- EVCO

- Arbuthnot

- RJG, INC.

- Philips Medisize

- SMC

- RTP

- Nordson EDI

If you're considering a future in plastics engineering, know that our industry partnerships provide a truly enriched educational experience. It's your direct pipeline to career success.